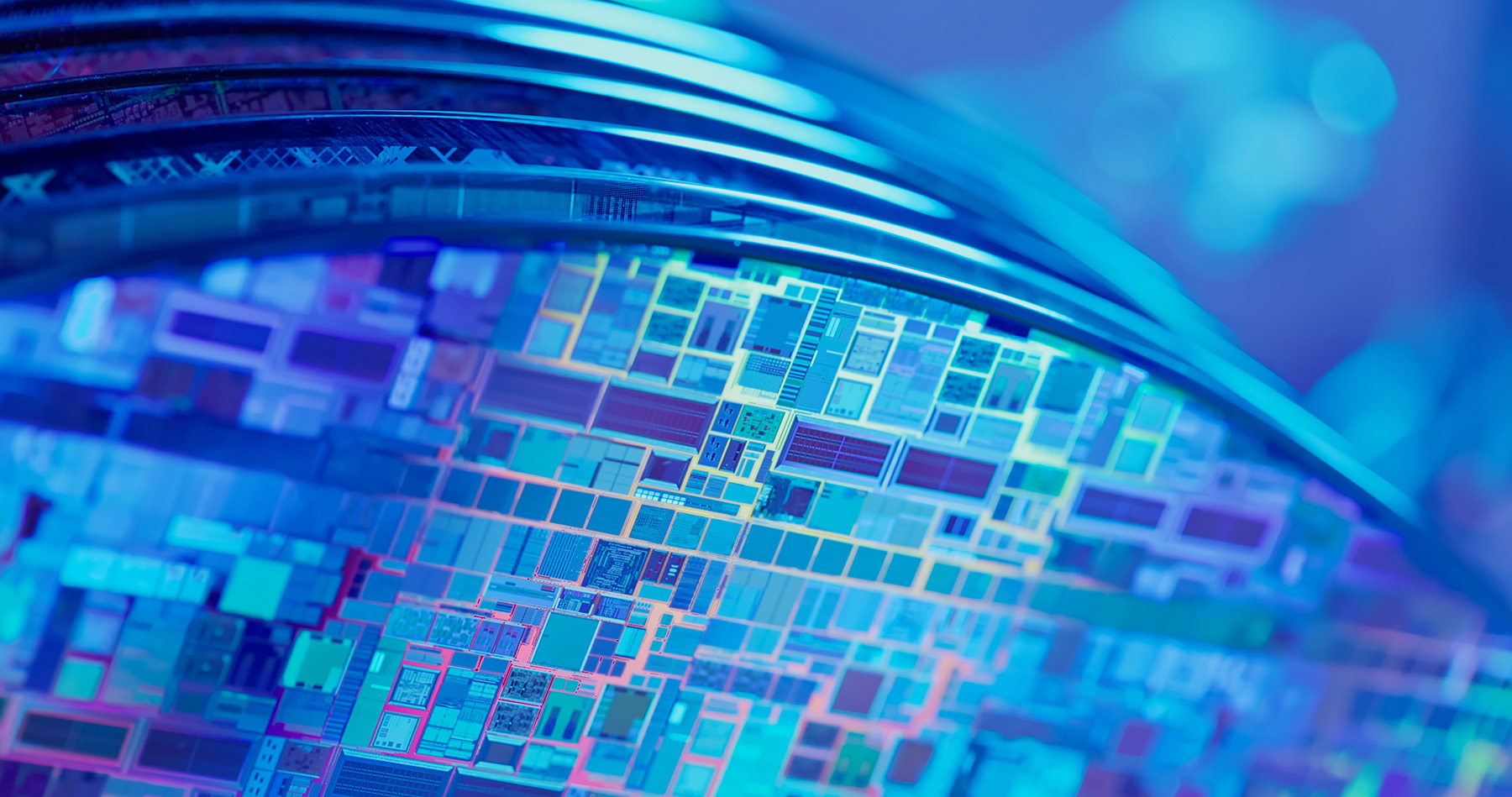

Amerimade was founded in 1992 in Silicon Valley. Working with the entire range of device manufacturers from start-ups and R&D facilities to the world’s largest device manufacturers, we developed design, engineering and manufacturing practices and procedures for wet chemical processing systems that have fostered stability and growth into other applications and markets for over 30 years.

Often combining solutions developed for Semiconductor and Data Storage applications, we have supported the growing MEMS and nano-device market since its inception. We now live surrounded by micro miniature devices such as pressure sensors, valves and accelerometers in cars, aerospace systems, cell phones, Drones, VR, etc.

Our geographic “backyard” provided us proximity to, and partnerships with the world’s most recognized players in the biotech fields. Utilizing our knowledge of wet chemical processing along with our library of process chamber and system designs, we develop specialized equipment solutions which fulfill the unique needs of these customers. This includes equipment used for research, diagnostic/lab purposes and patient therapy.

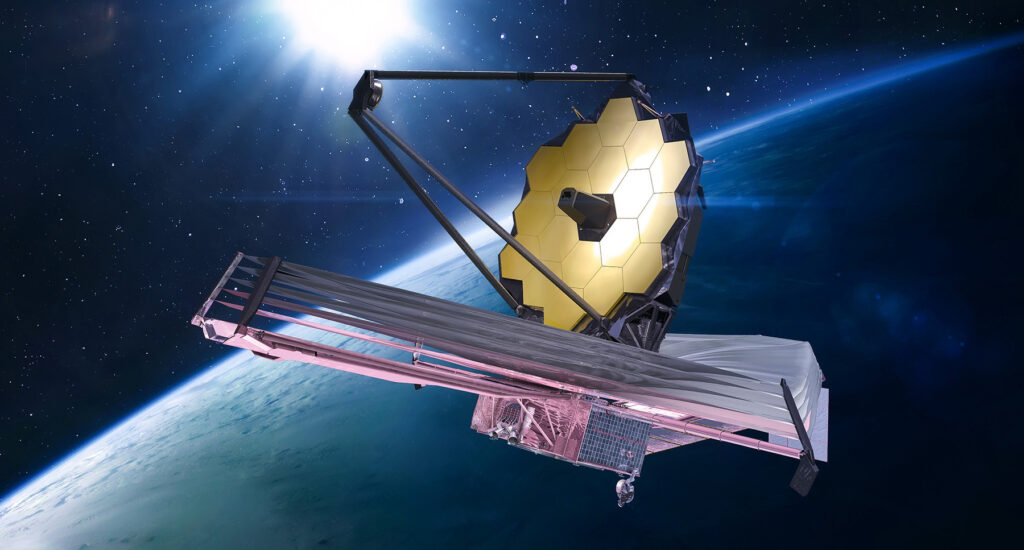

Amerimade Technology Inc has been a trusted supplier to Americas top Defense contractors for over three decades. Our tools have been used to manufacture Solid State Gyros, detonators, accelerometers, pressure transducers, Laser and electro-optic components used in today’s advanced military technology. We provide state of the art wet chemical process equipment for Satellite, Space telescope, communication, and transportation technology.

Global R&D related to solar-electric cells, solid state batteries, fuel cell, wind and related technologies continues. Amerimade has been part of these efforts for over 25 years by applying and tailoring processes first developed in Semiconductor and MEMS/NANO applications.

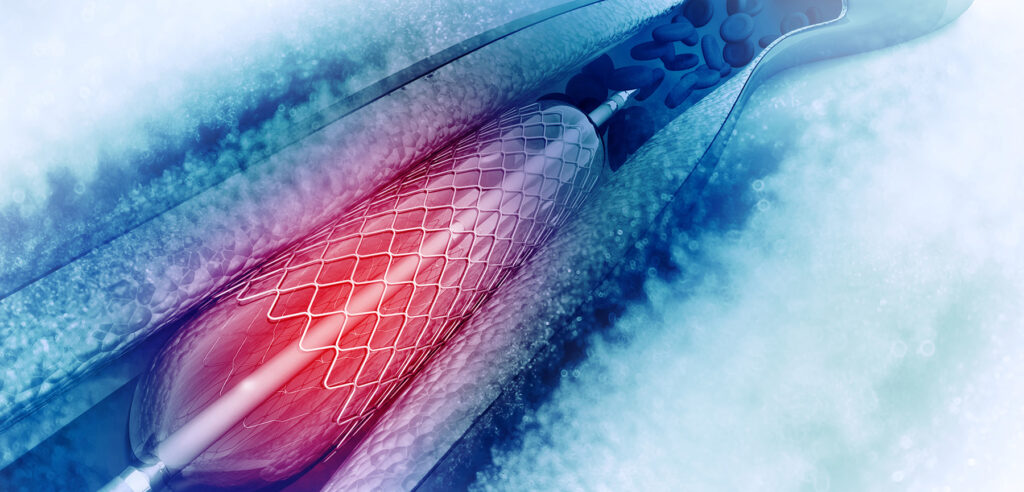

We design and manufacture specialized equipment to accommodate the unique requirements of the medical device industry. We offer fixture design and prototyping so that our customers’ products can be processed in conventional baths and rinse modules. We have turn-key and custom electropolishing stations with a variety of contact mechanisms, power supplies, and chemical management techniques. Many times, our equipment is used for Micro-plating continuous glucose monitoring sensors or electropolishing cardiovascular stents, cages, deployment devices, and many other applications. This industry utilizes our Manual, Semi-Auto, and Fully Automatic Wet Process Stations worldwide.